Engine Failure Prevented by AI?

The automotive industry is continuously challenged by the need to improve maintenance and diagnostic systems. Top engine manufacturers aim to

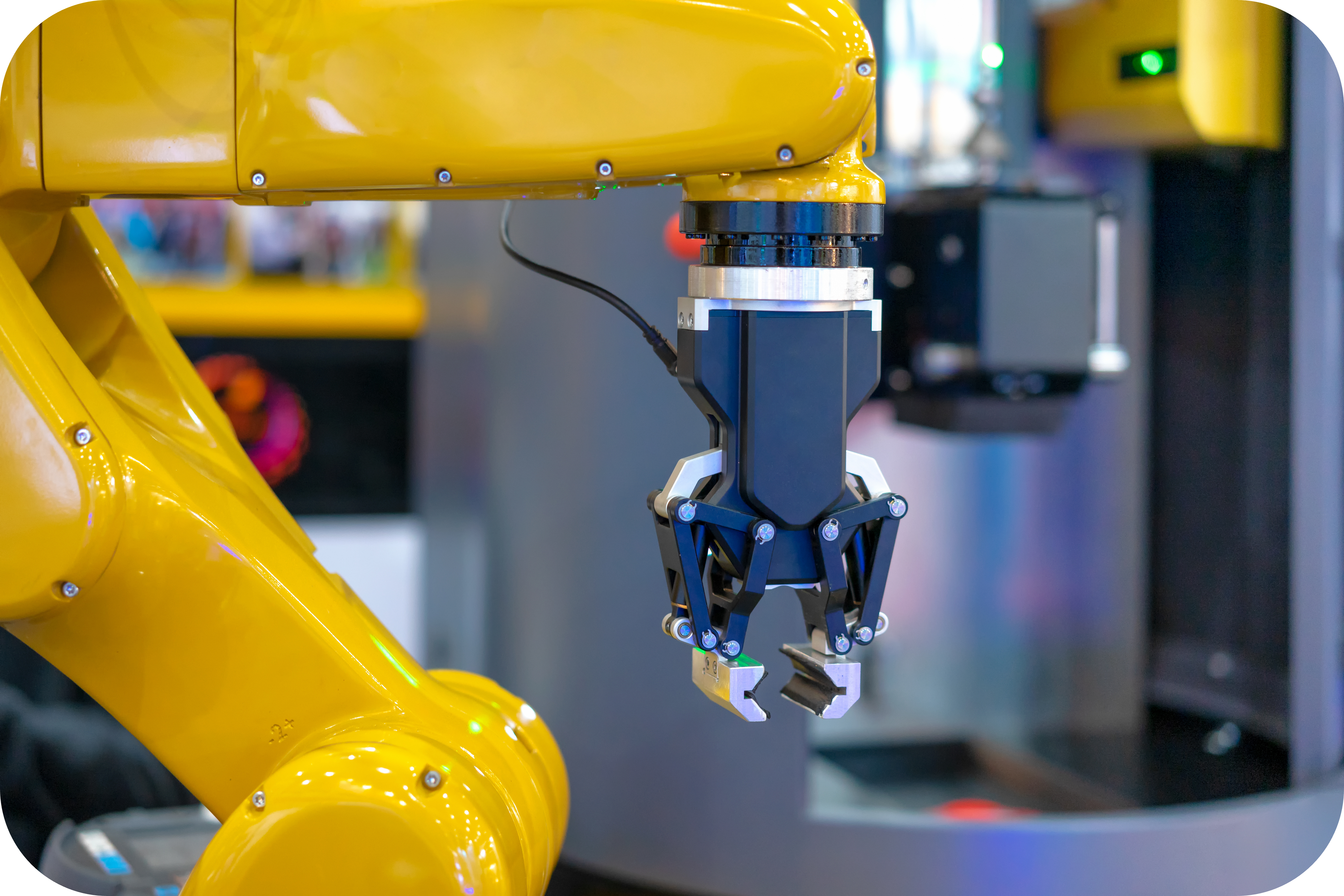

AI in Industry 4.0 facilitates predictive maintenance, real-time monitoring, and optimisation of production lines.

Process optimisation

Process optimisation

Identify inefficiencies, predict maintenance needs, and optimise production workflows with AI.

Autonomous Systems

Autonomous Systems

Enable self-operating machinery and systems, improving safety, efficiency, and decision-making in dynamic environments, while reducing human intervention and operational costs.

Predictive Maintenance

Predictive Maintenance

Utilise AI to anticipate equipment failures and schedule timely maintenance, minimising downtime and maximising productivity in manufacturing processes.

Anomaly Detection

Anomaly Detection

Swiftly identify and analyse deviations in manufacturing processes, enhancing quality control and preventing potential defects or system failures.

Automated Troubleshooting

Automated Troubleshooting

Streamline your customer service with smart, AI-powered troubleshooting engines, reducing response time and improving issue resolution.

Documentation Standardisation

Documentation Standardisation

Achieve consistency and accuracy in your support content with tools that automate the standardisation of documents, enhancing the overall quality of customer service.

Allow tasks to be performed with near-zero efficiency loss.

Deep Learning automation achieves super-human performance.

From quality control, predictive maintenance to logistics, our solutions have concrete benefits.

The automotive industry is continuously challenged by the need to improve maintenance and diagnostic systems. Top engine manufacturers aim to

The advancements in automotive technology have helped revolutionise the manufacturing industry. Despite the advances made, quality control remains predominantly reserved

How does Machine Learning really work? Find out how AI can optimise image anomaly detection.

© 2023 Gemmo AI. All rights reserved.