AI in Manufacturing Lumascape Guide

Artificial Intelligence in Manufacturing The global AI in manufacturing market size is projected to be $9.89 Billion by 2027. To put that into context, in 2019 it was valued at $840 million. And while the AI in Manufac...

Artificial Intelligence in Manufacturing

The global AI in manufacturing market size is projected to be $9.89 Billion by 2027. To put that into context, in 2019 it was valued at $840 million. And while the AI in Manufacturing Market can be easily segmented by application: Pharmaceuticals, Automotive, Heavy Metals, Textiles, and Machine Manufacturing but to name a few. Segmenting by AI solutions is a trickier task. That’s where our new tool the AI in Manufacturing Lumascape comes in handy. A tool designed to support teams looking to shape the future of AI in manufacturing.

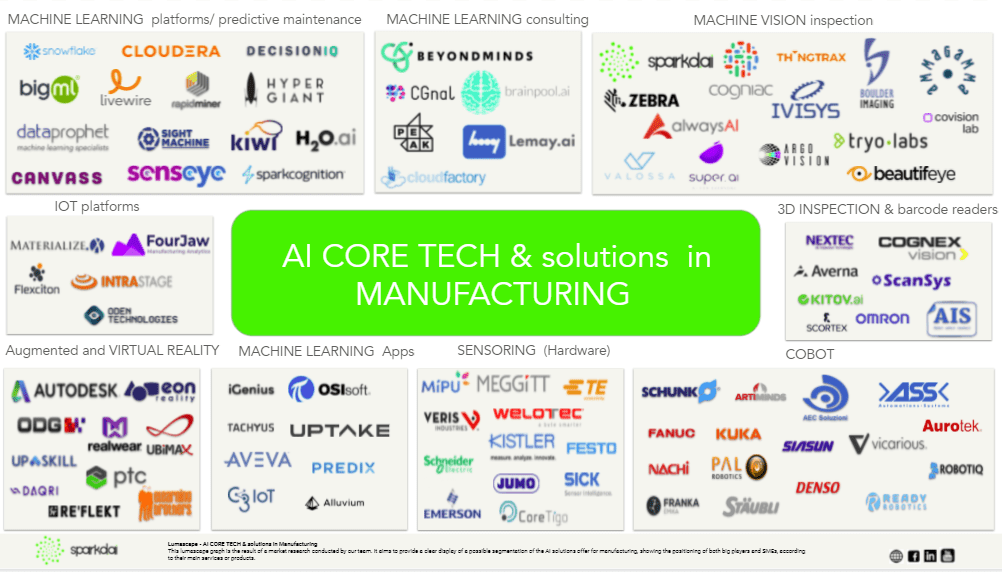

The Lumascape of AI in Manufacturing

This lumascape graph is the result of a market research conducted by our team here at Sparkd.AI. The aim is to provide a clear idea of the possible segmentation of AI solutions for manufacturing companies. While it shows the positioning of both the big players and SMEs according to their main services or products, it is by no means a conclusive list.

Here’s the breakdown:

- Machine Learning platforms/predictive maintenance

- Machine Learning consultancy

- Machine Vision inspection

- IOT Platform

- 3D Inspection & barcode readers

- Augmented Virtual Reality

- Machine Learning Apps

- Sensoring (Hardware)

- COBOT

Machine Learning platforms/predictive maintenance

Platforms for unifying, integrating, analyzing and sharing previously siloed data. All with near-zero management which facilitates unlimited scaling, concurrency and performance. Or predictive maintenance, allowing manufacturers to monitor the performance and condition of operations in a bid to reduce the likelihood of failure.

Predictive maintenance platforms enable scalable automation in supply chain management operation. A perfect solution for metric specific projects with simple data sets.

-> Common use cases include completion of repetitive tasks in manufacturing plants, or log-tracking PM platforms to alert faults and interruption in production cycles. Here are but a few of the key players providing these solutions:

Machine Learning consultancy

Consultancy on the use of systems that are trained by artificial intelligence to automate aspects of manufacturing companies operations. If your company has specific problems that can’t be solved with off the shelf AI solutions, crafting specific systems with a bespoke consultancy could be the best fit to tackle your challenges. The consultancy team would be just like an in-house ML team without the need to hire someone permanently.

Some ML consultancy firms are R&D teams hired to solve new challenging problems using cutting-edge technologies.

-> Common use cases include optimizing business operations to boost productivity and hit the right KPIs. Some of the key ML consultancy companies include the following:

Machine Vision inspection

Leveraging computer vision algorithms to inspect manufacturing supply chains is a game changer. Organizations can deploy a series of interesting practices to measure quality control, detect anomalies/faults and predict machine maintenance.

-> Common use cases include machine vision inspection throughout the production line. Think of the production of glass bottles, because bottlenecks are an extremely delicate part of the bottle they are often spoiled during bottling and sealing. Positioning one or multiple cameras throughout the production line can enable powerful levels of error-detection on the bottles – and even locate where on the bottle the defect lies.

Here at gemmo.ai, machine vision inspection is one of our fortes. If you’d like to discuss more about smart manufacturing examples, book in with our AI specialists today. Here are some of the other key players in machine vision inspection:

IOT Platform

The marriage of advanced manufacturing techniques with the internet of Things creates systems that are not only interconnected, but also communicate, analyse, and utilise data to drive intelligence into the physical world. From machine learning (ml), artificial intelligence, to edge/cloud/fog technologies, IoT platforms can fuel digital transformation in manufacturing companies through predictive models, digital twins, and fully automated workflows. Here’s some of the companies offering IoT solutions:

-> Common use cases include tracking data relating to a factor such as temperature with IoT devices and these devices linking up to optimise operational processes, adjust as needed and increase efficiency.

3D Inspection & barcode readers

The impact of AI in manufacturing when it comes to 3D inspection and barcode readers is a no brainer. Inventory is typically one of the largest assets a distributor or manufacturer can have, so optimizing how it’s managed is key for ensuring long term profitability. Using technology such as Radio Frequency Identification (RFID) enables automatic data tracking and collection, error reduction and less manual labour. Here are but a few of the key players to look out for within this space:

-> Case use cases include solutions relating to locating inventory in real time, eliminating cost of missing or incorrect data, verifying shopping quantities and reducing stock outs.

Augmented & Virtual Reality

As the use of augmented reality visors is growing in the manufacturing industry, the numbers of companies serving the segments are increasing. Thanks to their hands-free logic which allows operators to work in complete safety they are applied to areas of maintenance, training and error prevention . See key players listed below:

-> Common Use Cases include the remote maintenance of machines and plants, this reduces the frequency of maintenance operations that require experts manual instructions and intervention. Some companies and startups even offer the AR technology deployed via mobile devices (e.g., phones, laptops, tablets, etc.) and via wearable technology (visors).

Machine Learning Apps

App that leverages machine learning technologies to optimize workflows. Allows on-site managers and engineers to leverage real-time, proactive and easy to interpret insights in order to maximize production cycles and drive plant efficiencies. Here’s a few key players providing such solutions:

-> Common Use Cases include solving manufacturing problems like the detection of low-performing assets. This ensures action can be taken quickly, tracking and reducing the downtime of production cycles, and getting real-time production forecasts.

Sensoring (Hardware)

Any sort of hardware relating to manufacturers supply chains can capture some crucial data relating to the company’s operations. These sensing devices could be tracking data points ranging from product count or defects with cameras, to pressure or sound with barometers or microphones. Here’s some of the key companies offering but a few of the many types of sensory devices useful in manufacturing:

-> Common use cases include temperature and vibration sensor. Using such a sensor can help monitor the health of a motor in a machine by measuring the temperature and vibration of the machine to figure out normal running patterns. The information can then be easily relaid by synching up with other AI technologies making the data available and uncovering patterns in machine behaviours.

COBOT

Collaborative robots (cobots) provide manufacturers with safe, versatile, and easy-to use automation that supports human laborers. Leveraging this AI in manufacturing sector helps meet manufacturing demands, particularly useful for industries hard-hit by hiring challenges. Here’s a few of the key players in the field of Cobots:

->Common use cases of Cobots in manufacturing include machine tending, process tasks, packaging, quality inspection, and finishing tasks like polishing, grinding and deburring.

Conclusion

The role of AI in manufacturing is integral to the growth of the industry. Many examples of AI in manufacturing demonstrate the huge benefits that can be seen from it’s deployment. Many AI projects in manufacturing however, do not succeed. This is why choosing the right solution for your organization is key to the success of your AI project. You can Download the Lumascape to help evaluate your options.

Ready to get you your AI project off to the right start? Try out our free tool The Periodic Table of Deep Learning Elements designed to help do exactly that.